At 10:43am on April 17, Southwest Airlines Flight 1380 took off from New York's LaGuardia Airport bound for Love Field in Dallas with five crew and 143 passengers aboard. But just over 20 minutes into the flight, at an altitude of about 30,000 feet somewhere above Hershey, Pennsylvania, the left engine of the Boeing 737-700 exploded, blowing off its cowling. Debris shattered a passenger window, fatally injuring a woman seated next to it. With the cabin rapidly decompressing and an engine gone, the crew immediately began a descent, diverting toward Philadelphia for an emergency landing.

American commercial airline travel has been remarkably safe over the last decade: it has been more than 9 years since the last fatality on a US airline. Worldwide, 2017 was the safest year for air travel on record. Incidents like this one—a death caused by engine debris—are exceedingly rare; the last time engine debris killed an American commercial airline passenger was in 1996.

But it's not like this was a random act of God. What happened aboard Flight 1380 appears to have been "uncontained engine failure" in the front portion of the left engine—a failure of one of the engine's fan blades causing a spray of debris that rips through the walls of the engine (hence the "uncontained" part). This isn't the first time that a Southwest jet has experienced such a failure: another Southwest 737-700 using the same type of engine (a CFM56-7B) occurred in August of 2016, with no fatalities. And a United Airlines 777 flying from San Francisco to Hawaii suffered an engine failure caused by a broken fan blade last month, though the failure was contained and the aircraft landed safely.

What a flight! Made it!! Still here!! #southwest#flight1380pic.twitter.com/Cx2mqoXVzY

— Joe Marcus (@joeasaprap) April 17, 2018

A cylinder of spinning swords

Turbofan engines are the standard propulsion plant for commercial aircraft. They're basically two engines in one. At the core of a turbofan is a turbojet, which compresses and heats air to push it through turbines and out the back of the engine for thrust. But instead of just using the rotational energy created by the turbines to compress air, the engine also turns a much larger fan at the very front of the engine that acts like a ducted propeller—pushing air not just into the jet engine but also into a "bypass" channel around the core engine for additional thrust. As a result, while turbofan engines may not get the raw performance of a turbojet, they're loads more efficient at moderate speed. Most turbofan engines today are "high bypass, low specific thrust"—meaning, they generate much less of their thrust from the turbojet at their core than from the bypass thrust from the fan.

The engine used by Southwest's 737-700s, the CFM56, is the most popular high-bypass turbofan engine in the world. Built by CFM International, a joint venture of Safran Aircraft Engines of France and General Electric Aviation, the CFM56 family of engines has been in service since 1974; there are more than 30,000 of them in service with more than 500 different air carriers, and, as a whole, CFM56 engines have more than 800 million flight hours, with remarkably few major failures. The engine used by Southwest's 737-700s—the CFM56-7B—is used on 6,700 aircraft and has seen more than 350 million cumulative flight hours,

But a number of factors can lead to even the most reliable engine failing. With turbofans, the most frequent causes are maintenance errors and metal fatigue.

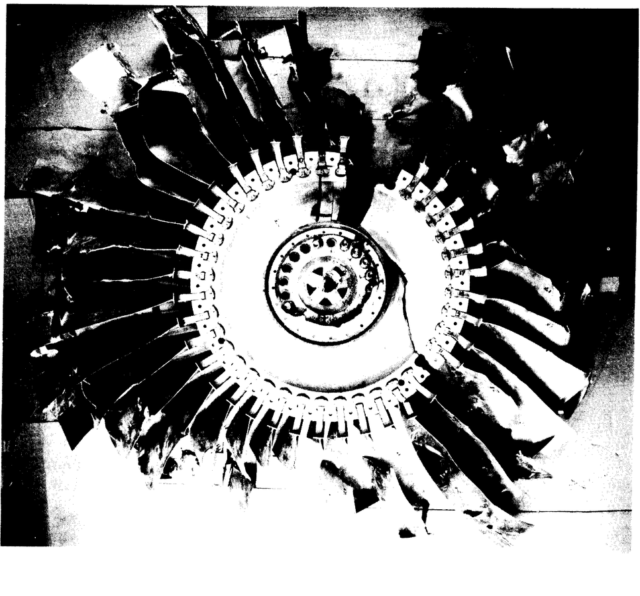

As the engine gets older, the blades of the fan (scimitar shaped, hollow, and made of a titanium alloy) may become more brittle and begin to crack. Cracking can also be caused by other factors—as in the case of the July 6, 1996 failure of an engine aboard Delta Airlines flight 1288. In that incident, an engine on the McDonnell-Douglas MD-88 hurled fan blades through the engine casing and into the airplane's passenger cabin, killing two passengers. Inspection of the engine after a previous repair had failed to detect a large crack in the fan's hub.

And when a cracked fan is spinning at about 8,000 revolutions per minute, it can become a deadly projectile—either headed outward through the engine casing, or back into the jet portion of the engine, causing even more shrapnel amongst the compressor rotors and a full-on engine explosion.

Spontaneous shrapnel

While any broken blade in a jet engine is going to be destructive to the engine itself, the fan's position outside of the engine proper and its larger size and momentum also make the fan dangerous if it fails. One blade flying free could bounce around inside the cowling, breaking loose other fan blades, creating a hail of spinning sword-like debris. The engine cowling needs to be extremely resistant to damage from a fan failure to prevent the blades from flying out and striking the body of the aircraft–making sure that the failure is a "contained failure."

But in some cases, a fan blade breaks free with enough kinetic energy that it becomes an extremely large-caliber bullet, breaking other fan blades and passing through the engine housing. In the most catastrophic cases, such as the crash of United Airlines Flight 232 in Sioux City in 1989, the flying pieces of fan blades can cut through other vital aircraft systems. The same year, a fan blade failure on British Midland Flight 92—a 737 using an earlier version of the CFM56 engine—led to a crash in Kegworth, England, in which 47 died and 74 sustained serious injuries.

Fortunately, the more recent incidents involving uncontained engine failures have not been on a UAL 232 scale. While the Delta incident in 1996 killed a mother and child and left five others injured, there had been no fatalities in engine failure incidents since. Most recently, in August of 2016, in an incident similar to this week's, Southwest Airlines Flight 3472 from New Orleans to Orlando suffered an uncontained failure of its left engine, blowing off the engine inlet—resulting in passenger photos almost identical to the ones posted by passengers of Flight 1380. As with this week's accident, the aircraft experienced cabin depressurization, but not because of a blown window—a 5-inch by 16-inch hole was found in the fuselage just above the left wing, but no fan blade or engine cowling material managed to penetrate into the passenger compartment.

The missing fan blade from Flight 3472 was never found, and the NTSB investigation of that incident is still underway. But the fracture surface that remained showed signs of fatigue crack growth.

It's highly likely that examination of the engine of Southwest Flight 1380 will find the same tell-tale signs of engine fatigue. The engines on the aircraft—a "Next Generation" 737-700 with the registration number N772S, put into service in 2000—have been used for about 40,000 flights, and about 10,000 of those since the aircraft's last major overhaul. While that's not unusual for Southwest, which has one of the older average-aged fleets of aircraft in the industry, it's likely that Southwest will end up increasing the frequency of engine overhauls as a result of this accident.

But remember: air travel is still a lot safer than driving.

[contf] [contfnew]

Ars Technica

[contfnewc] [contfnewc]